DNP Commences Operation of Metal Mask Production Line for OLED Manufacturing at Kurosaki Plant

- Compatible with 8th generation glass substrates -

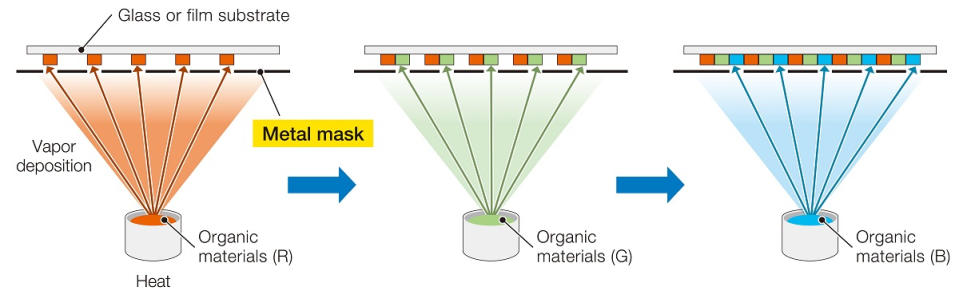

TOKYO, June 12, 2024--(BUSINESS WIRE)--Dai Nippon Printing Co., Ltd. (DNP, TOKYO: 7912) announces that in May 2024 we commenced operation of a new metal mask production line for manufacturing Organic Light Emitting Diode (OLED) displays at our Kurosaki Plant situated in Kitakyushu City, Fukuoka Prefecture. In response to the increasing demand for larger OLED displays.

The new line will produce large-scale metal masks compatible with 8th generation (G8) glass substrates for larger OLED displays that are introduced in various IT devices. G8 substrates are significantly larger than the current 6th generation (G6) substrates, facilitating increased production efficiency.

[Full-Scale Ops]

OLED displays are increasingly being introduced into IT products such as smartphones, tablets, notebooks, and monitors. There is a growing need for larger displays, and OLED panel manufacturers are promoting mass production with large 8th generation glass substrates, which exhibit a higher production efficiency than the current 6th generation. Anticipating such needs, DNP has established a production system for the manufacture of metal masks compatible with the G8 size on the new line at our Kurosaki Plant.

DNP is constantly optimizing its Business Continuity Plan (BCP) and will further promote BCP with the start of operations of the new line, making it possible to provide a backup for our existing metal mask production base at our Mihara Plant, in Hiroshima Prefecture.

With the launch of full-scale operations at the Kurosaki factory DNP plans to double metal mask production capacity.

[Looking Ahead]

DNP will gradually increase facilities at the Kurosaki Plant, while constantly being aware of, and analyzing demand trends. DNP has designated the Digital Interface-Related business, including metal masks, as a growth area in its medium-term management plan for FY 2023 to 2025, and will strive to further expand business through concentrated investment of management resources.

About DNP

DNP was established in 1876, and has become a leading global company that leverages print-based solutions and the strengths of its growing number of partners to engineer fresh business opportunities while protecting the environment and creating a more vibrant world for all. Today we develop and refine technologies for conducting electricity, controlling light and heat, decorating surfaces, and protecting content, effectively becoming a standard-setter for the industry of the future.

View source version on businesswire.com: https://www.businesswire.com/news/home/20240607127204/en/

Contacts

Media contact

DNP: Yusuke Kitagawa, +81-3-6735-0101 kitagawa-y3@mail.dnp.co.jp

Yahoo Finance

Yahoo Finance